Last week our CEO, Greg Kingham, spoke to Packaging Insights about Camvac Production during COVID-19.

Read the full inteview below or on Packaging Insights here;

Camvac has leveled-up the production output of its medical and core food packaging solutions by transitioning from a two-shift to a three-shift 24-hour operation as the COVID-19 pandemic drives up demand. Europe’s first supplier to produce food-grade metalized OPP and PET packaging, Camvac is experiencing particularly high demand for its mono-material tray lidding films, which offer high barrier options. Greg Kingham, CEO, takes PackagingInsights inside Camvac’s enhanced operations to discuss international supply chain challenges, employee safety and how established product lines are trumping the latest eco-friendly innovations in these unprecedented times.

“Worldwide, governments are recognizing that food and medical manufacturers of flexible packaging are playing a critical role in the battle against COVID-19. Camvac’s business operation places it as a central supplier of essential products and services to the healthcare, food and liquid packaging markets. Without primary packaging, these supply chains will be compromised and the battle against COVID-19 hampered,” Kingham affirms.

Camvac reports increased demand for its medical and core food packaging. In particular, Extrapet recyclable lidding film has seen a “massive increase” in demand. Extrapet is a transparent barrier polyester laminate, which is used in a wide range of lidding film applications, including processed meats, fresh meats, poultry, pasta, vegetables and bakery, where presentation and freshness are critical. Extrapet is an all-PET, mono-material structure available in peel and non-peel, anti-fog and high barrier options.

“We believe that the demand increase for our food packaging materials is a result of the food industry catching up with demand from the consumer panic buying but also our customers increasing their stock levels,” Kingham explains.“To cope with the increased demand and maintain supply to our critical food and medical markets, along with our other specialty markets, Camvac has increased its manufacturing output by moving from a two-shift operation to a three-shift 24-hour operation.”

Since the outbreak, Camvac has also witnessed an increase in demand for its liquid packaging films, Kingham notes. “This increase is not just short-term to replace used stock as customer orders are being brought forward to meet current demand and future orders placed at the same time to ensure stock levels remain positive.”

A spanner in the sustainability works

The impact of COVID-19 is so great that it has even shown signs of hindering the seemingly unstoppable environmental sustainability mega-trend, at least temporarily. Pre-COVID-19, the demand for new environmentally-friendly packaging was “constantly increasing,” Kingham tells PackagingInsights. “However, over the last month, we have seen a decrease in the demand for our sustainable packaging solutions with our customers opting to take stock of our established product lines.”

Accordingly, new developments at Camvac have been put aside to allow the Technical & Development Team to fully concentrate on supporting the supplier’s medical, food and liquid packaging demands.

Kingham is keen to illustrate, however, that Camvac is now able to offer 70 percent Post-Consumer Recycled (PCR) films, which can include barrier properties for use within the food lidding packaging marketplaces. The PCR films are designed primarily for heat-sealed tray lidding applications.

“In a longer pipeline, the Technical & Development team are working on a sustainable packaging solution called Cambag for our liquid packaging market. Cambag will be an environmentally-friendly high barrier laminate that is fully recyclable for the Bag in Box market. It will be available in clear and metalized laminate options,” Kingham highlights.

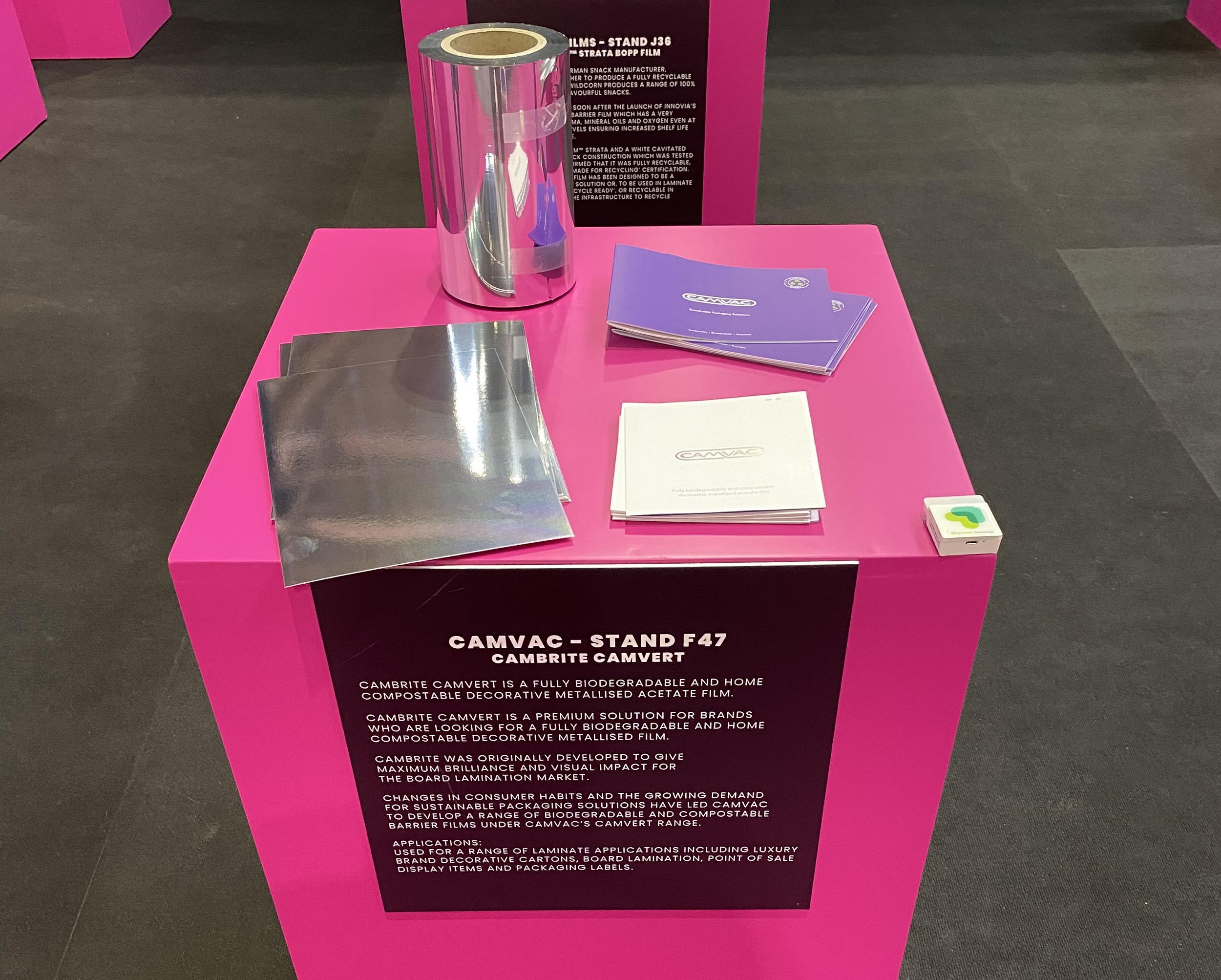

The COVID-19 outbreak has also overlapped with the launch of Camvac’s latest sustainable film, Cambrite Camvert, a fully biodegradable and home-compostable decorative metalized acetate film. “The interest is constantly growing with this film and with the enforcement of non-essential travel being in place, new marketing methods had to be thought of,” Kingham says. “Our Marketing Team has turned its focus to direct marketing to help this situation.”

Circumventing supply disruptions

Camvac supplies its products internationally and relies on an international supply of raw materials. The company has reported longer lead-times in raw material supply from mainland Europe, particularly Spain and Italy, two of Europe’s worst affected countries in the COVID-19 pandemic.

Kingham puts the raw material delays down to more stringent border controls and checks and a reduction in transport availability. Camvac has increased its raw material stock levels to limit the potential impacts of supply chain disruptions.

The same issues apply to Camvac’s distribution of products. “Our transport companies have been experiencing labor supply issues. This hasn’t stopped deliveries, just extended the lead-times,” he notes.

“Some of our customers further afield like in Australia and Asia have brought forward their orders to compensate for the extended shipping times. Camvac’s Purchasing Team is working tirelessly to minimize the disruption this could cause on our manufacturing output.”

“As a global business, we are also having to closely monitor individual country exchange rates against the pound for volatile changes as a result of the impact COVID-19 is having on economies around the globe,” Kingham adds.

Safety first

Camvac’s production increases have not come at the expense of employee safety and the company has taken “drastic action” to ensure that. In line with government advice, individuals that can reasonably work from home are doing so and office areas have been reorganized to allow for social distancing for colleagues who are required to attend site. All site visits and customer travel have been canceled.

Kingham tells PackagingInsights that Camvac has implemented “rapid expansion” of its IT capacity to increase the number of people who can work from home while conference calls are taking the place of face-to-face meetings. The supplier has also commenced daily COVID-19 Crisis Management Team Meetings to ensure that new issues are tackled immediately. Meanwhile, the hygiene team is working increased hours to support a safety regime.

“[24-hour manufacturing] is only possible because of the Camvac Team, who are absolutely committed to keeping our business operating in this time of need. Central to our operations is the Production Team, which has shown remarkable flexibility, commitment and resilience to the ever-changing situation. These swift reactions and combined team effort have and will continue to ensure that Camvac remains fully open for business and able to supply its customers in the difficult times ahead of us all,” Kingham concludes.

Camvac have risk assessed the COVID situation and will continue to monitor the pandemic daily. Our latest COVID Risk Assessment can be found here; RA Corona virus update 04.11.20

Anyone wishing to place further orders should contact their normal Sales Managers and of course we are open to discuss new opportunities about our flexible packaging solutions through our contact us form on our website or general sales enquiry email; info@camvaclimited.com